Locomotive Pickup Wheels

Locomotive wheels pick up the current from the rails so they must be insulated to avoid shorting out the circuit.

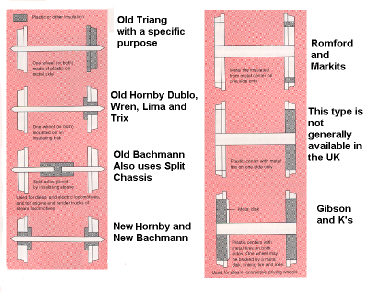

This insulation can take many forms. Below are some examples of the more common forms available:

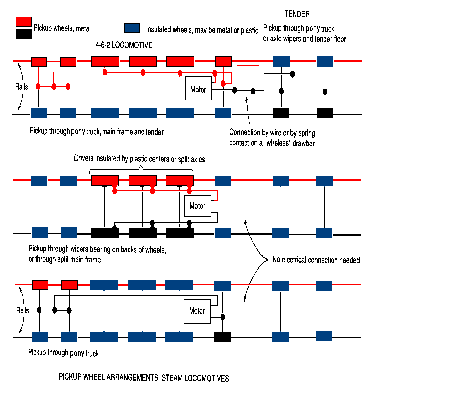

BEFORE fitting any decoder to any locomotive, you will need to positively identify all of the pickup wheels on the locomotive and its tender. Look for all-metal wheels running in metal frames or wheels with metal tyres with wiper contacts.

There is not much standardisation in the arrangement of pickup wheels on locomotives but however they are arranged, their job is always to provide a steady, uninterrupted flow of power to the motor.

Although no standard is in place, over the years a number of common systems have been developed.

One standard that is in place is the NMRA S9 Standard. This applies to pickup wheels, to the way that they are connected to the motor such that the direction in which the locomotive moves is set.

Without going into technicalities, it is sufficient for our needs at the moment to say that if a POSITIVE potential is applied to the RIGHT-HAND rail it will produce FORWARDS motion in the locomotive. This is more commonly referred to as ‘The Right-Hand Rule’, as we have already seen in an earlier article.

Generally, the configuration most often found on steam locomotives is to have a pickup from the RH Engine wheels and the LH Tender wheels.

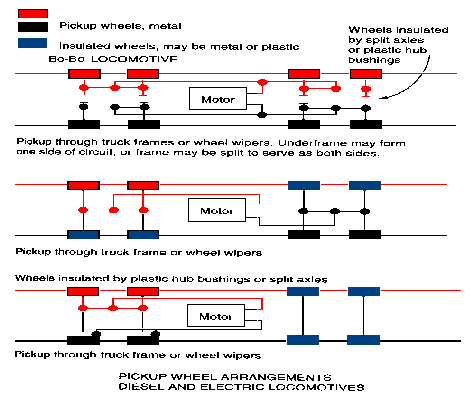

Diesel and Electric locomotives have three basic arrangements.

Although the merits of the pickup schemes depend somewhat on the whims of the manufacturers and the designers, there is one common truth for us to consider –

The locomotive with the most wheels picking up current will work best.

The more pickup wheels a locomotive has, the less chance there is that the current / signal path will be interrupted.